Mining today uses machines for hard work. A Heavy Duty Jaw Crusher for Mining breaks big rocks and ores. These crushers get materials ready for the next mining steps. Workers trust these machines to make mining safe and help them work well. Mining sites use jaw crushers because they make mining faster. Mining needs strong equipment that works all the time.

Key Takeaways

-

Heavy duty jaw crushers crush big rocks into small pieces. They use two jaws, one stays still and one moves. This makes strong pressure to break the rocks.

-

Operators can change the space between the jaws. This controls how big or small the crushed pieces are. Hydraulic systems help make these changes fast and safe.

-

These crushers are made very strong. They can crush hard rocks and work all the time. This helps mining teams finish jobs faster and stay safe.

-

Checking for worn parts and adding oil often is important. This keeps jaw crushers working well and stops expensive problems.

-

Workers must follow safety rules and get training. This helps the crushers run smoothly and keeps everyone safe during work.

How Jaw Crushers Work

Crushing Mechanism

A jaw crusher uses a simple crushing method. It has two main plates called jaws. One jaw does not move. The other jaw moves back and forth. Rocks go into the crushing chamber. The moving jaw pushes rocks against the fixed jaw. This creates strong pressure. The rocks break into smaller pieces. This happens again and again. The rocks get smaller each time. They become the right size for the next mining step.

Many mining sites use jaw crushers operate in modern mining first. These machines crush hard materials like granite and ore. The crushing happens in a V-shaped chamber. This shape helps guide rocks into the jaws. It makes crushing fast and easy. Workers trust jaw crushers for steady results.

Tip: The crushing works best when the rock size fits the machine. Rocks that are too big can slow things down and wear out parts.

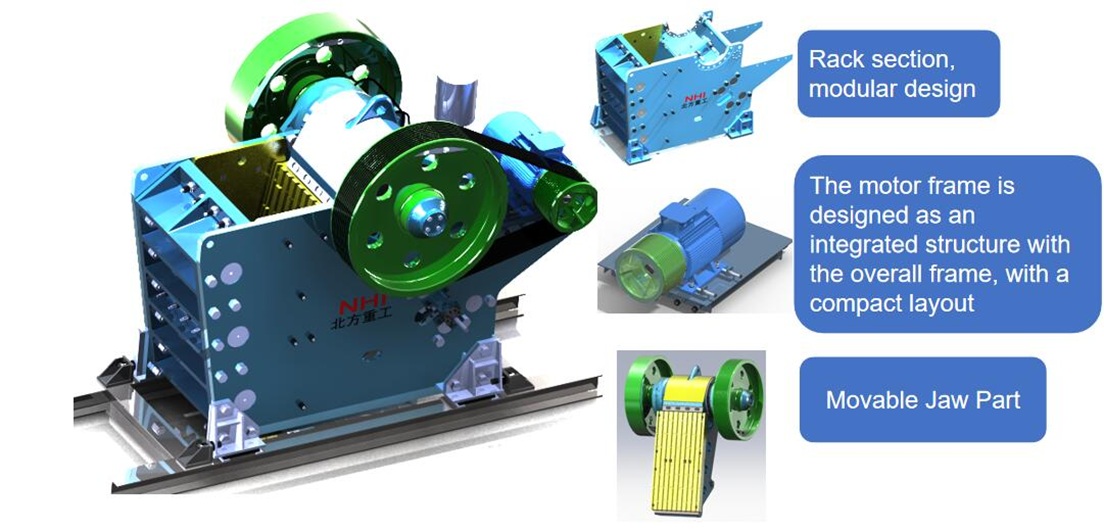

Key Components

A jaw crusher has important parts that help it crush rocks:

-

Fixed Jaw Plate: This plate does not move. It forms one side of the chamber.

-

Moving Jaw Plate: This plate moves to crush the rocks.

-

Pitman Arm: This strong arm connects to the moving jaw. It gives the force needed for crushing.

-

Toggle Plate: This part is a safety device. It breaks if there is too much pressure. This protects the machine.

-

Flywheel: This heavy wheel stores energy. It helps the jaw crusher run smoothly.

-

Frame: The frame holds all the parts together. It gives the jaw crusher its strength.

All these parts work together. They make jaw crushers strong and reliable. Each part must do its job. Regular checks and care keep the jaw crusher working well.

Crushing Chamber Adjustment

Operators can change the crushing chamber size. This controls how big or small the output is. The gap between the jaws can be made smaller or bigger. A small gap makes finer material. A big gap lets larger pieces pass through.

Most new jaw crushers use hydraulic systems. Operators can change settings quickly and safely. This helps mining teams get the size they need. It also saves time and keeps the crusher working well.

Some jaw crushers use simple mechanical adjustments. Others have advanced controls for exact changes. Being able to adjust the chamber makes jaw crushers useful for many mining jobs.

Note: Adjusting the chamber helps stop blockages. It keeps the jaw crusher working smoothly. Operators should check the settings often for best results.

Heavy Duty Jaw Crusher for Mining

Primary Crushing Role

A heavy duty jaw crusher for mining is important at the start. Workers use it to break big rocks into smaller pieces. The jaw crusher has two strong jaws. One jaw stays still. The other jaw moves back and forth. This movement makes strong pressure. The pressure breaks the rocks. Mining teams use jaw crushers to get materials ready for the next steps. The machine must handle big rocks and lots of material. Many mining sites use mobile jaw crushers. These machines are easy to move around.

Handling Hard Materials

Mining sites often have hard rocks. A heavy duty jaw crusher for mining is made with strong materials. The fixed jaw and moving jaw can crush tough rocks. They do not wear out fast. Mobile jaw crushers press rocks between the jaws. This breaks even the hardest ores. These machines can take in big, blocky rocks. They make the output even in size. Jaw crushers work with many types of rocks. But they may have trouble with very big or sticky rocks. Jaw crushers cost less and are easier to fix than other machines. This is why many mining sites use them.

Note: Jaw crushers are easier to adjust and fix than some other machines. This helps mining teams keep working without problems.

Continuous Operation

Mining needs machines that work all day. A heavy duty jaw crusher for mining is made to run in tough places. The strong frame and simple design help it last long. Mobile jaw crushers have new features like speed controls and prescreens. These features help control how crushing happens. They also help the machine crush more rocks. Operators can change settings for each job. Mobile jaw crushers meet high demand. They help mining teams finish their work.

Operation in Mining

Material Feeding

Operators begin by putting big rocks into the feed opening. Mobile jaw crushers use machines like loaders or excavators for this job. The rocks go into the hopper. Feeding must stay steady to keep the chamber full. A steady flow helps the jaw crusher work well. If feeding stops, crushing slows down. The output gets lower. Operators watch the size of the rocks. This helps stop blockages. They do not put in too many rocks at once. This keeps the machine safe and the output even.

Crushing Cycle

The cycle starts when rocks enter the chamber. The moving jaw pushes rocks against the fixed jaw. This breaks the rocks into smaller pieces. Mobile jaw crushers repeat this cycle many times each minute. The crushing force stays strong every time. The jaw crusher works until rocks are the right size. The process shapes the output for the next mining step. Operators check the chamber often. They make sure crushing is smooth and the output fits mining needs.

Discharge and Output Control

After crushing, the output falls out from the bottom. Operators can change the gap between the jaws. This controls how big or small the output is. A small gap makes finer output. A big gap lets larger pieces out. Mobile jaw crushers use hydraulic systems for fast changes. This helps operators match the output to the mining site. Steady output keeps other machines working well. Operators watch the output to stop jams. This keeps the jaw crusher working smoothly.

Tip: Checking the output size often helps stop problems. It keeps the crushing process steady.

Automation and Safety

Modern mobile jaw crushers use automation for safety and better work. Automated systems control crushing speed and output size. Sensors look for blockages and can stop the jaw crusher. Hydraulic changes let operators adjust settings without stopping the machine. Safety features protect workers while they work.

Operator training is needed for safe and good jaw crusher use. Training teaches these main points:

-

Operators follow the manufacturer's instructions and safety rules.

-

They check the jaw crusher before starting to make sure it is safe.

-

Operators wear safety gear like hard hats, glasses, and boots.

-

They learn lockout/tagout steps to shut down the jaw crusher safely.

-

Operators never clear blockages or adjust the jaw crusher while it runs.

-

They follow maintenance steps and keep the area clean.

-

Emergency training covers shut-off switches, fire safety, and evacuation.

-

Operators report safety concerns and follow communication rules.

-

Contractors and visitors get safety briefings before entering the site.

These steps help keep mining safe. They make sure the jaw crusher gives steady output during all work.

Jaw Crusher Advantages

Durability

A jaw crusher is built to be very strong. Mining teams use it in rough places every day. The frame and jaws are made from heavy-duty steel. This steel does not wear out fast from crushing rocks. The moving jaw and fixed jaw can crush hard rocks without breaking. Many operators pick a jaw crusher because it lasts a long time. If you take care of it, it works for years. Regular checks and easy repairs keep it running. A strong jaw crusher means less time fixing and more time working.

High Capacity

Mining sites need machines that can handle lots of material. A jaw crusher has high capacity for this job. The wide feed opening lets big rocks go in. The crushing chamber can crush many tons each hour. This helps mining teams finish faster. The jaw crusher keeps working without long breaks. Steady output helps other machines do their jobs too.

Tip: High capacity helps the site move forward without delays.

Efficiency

Efficiency is important in mining. A jaw crusher uses a simple action to break rocks fast. The moving jaw pushes rocks against the fixed jaw. This happens many times each minute. The process uses energy well and does not waste much. Operators can change the chamber for the best size. Hydraulic systems make these changes quick. An efficient jaw crusher saves time and money for mining teams.

Adaptability

Mining sites change a lot. A jaw crusher can adjust to new jobs easily. Operators can change the chamber for different rock sizes. The machine works with many kinds of materials, soft or hard. Some jaw crushers have features like speed controls or prescreens. These help match the crushing to each job. The jaw crusher fits many tasks, so it is a smart pick for mining.

A jaw crusher helps mining teams handle new problems and keep working.

Maintenance and Selection

Wear Parts

Mobile jaw crushers work hard every day. Their wear parts get hit and pressed a lot. The main wear parts are jaw plates, cheek plates, and toggle plates. These parts touch rocks and ores when crushing. Over time, these parts wear out and need to be changed. Operators should check these parts often. Worn plates can make crushing weaker and the output uneven. Changing wear parts on time keeps the crusher working well. It also stops bigger problems from happening.

Tip: Operators should keep extra wear parts ready. Fast replacement means less waiting and keeps mining on track.

Lubrication

Good lubrication helps jaw crushers last longer. The main bearings, like the eccentric shaft and pitman bearings, need special care. These bearings often use spherical roller types. They handle shock and shaking well. Operators should use grease that stays thick under heavy loads. A lithium complex grease with high base oil viscosity, like Jet-Lube Jet-Plex EP™ Grease, works well for these machines. This grease protects against wear and keeps the bearings moving smoothly, even during tough jobs.

-

Lubricate all main and pitman bearings often.

-

Use grease that can handle heavy loads.

-

Keep dirt and water away from grease spots.

-

Check seals and change them if they are broken.

Troubleshooting

Problems can happen while using the crusher. Common issues are strange noises, shaking, or uneven output. Operators should listen for new sounds or feelings. These signs might mean loose bolts, worn parts, or blocked chambers. Quick checks and fixes stop bigger failures. Keeping a log of problems helps find patterns and plan repairs.

Choosing the Right Jaw Crusher

Picking the right jaw crusher depends on the job. Operators should look at the size and hardness of the material. They should also check the needed output size and capacity. Features like hydraulic adjustment, automation, and easy maintenance make a crusher better. Comparing models and talking to suppliers helps mining teams pick the best one for their needs.

A good choice means better work, less waiting, and safer mining.

Heavy duty jaw crushers are very important in mining today. They help workers crush hard rocks so work does not stop. These machines are strong, work fast, and can change for different jobs. Mining teams should look at what their site needs. They can check different crusher models and plan to take care of the machines often.

Picking the right jaw crusher helps keep mining safe and steady.