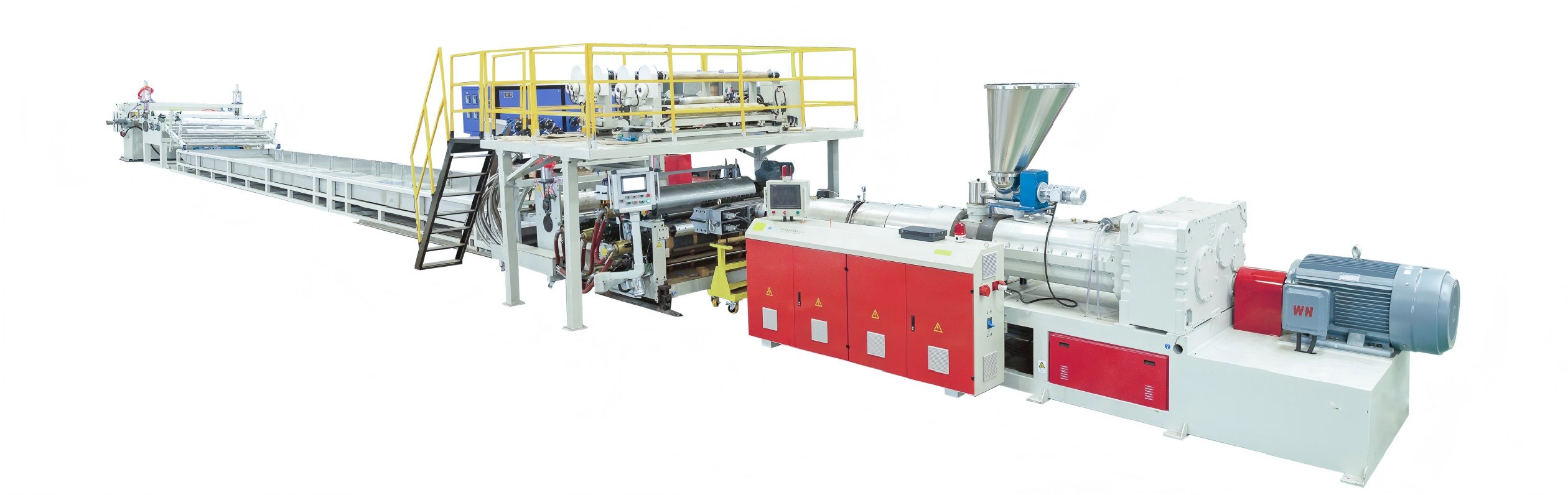

With the booming market for WPC (wood-plastic composite) production lines, numerous manufacturers have sprung up, resulting in inconsistent product quality. For companies looking to invest in WPC production, choosing the right production line is crucial; otherwise, they may face frequent equipment malfunctions and substandard product quality. However, by focusing on the following two certifications, many pitfalls can be avoided.

International Quality System Certification: A "Passport" to Quality

ISO 9001 international quality system certification is a globally recognized quality management standard. It acts like a "passport" to quality, directly reflecting a manufacturer's standardization and rigor in quality management. For WPC production line manufacturers to obtain this certification means they have a complete and rigorous quality control system at every stage, from raw material procurement and production process control to finished product inspection.

As an example of best practices in the industry, some manufacturers, after obtaining ISO 9001 certification, become more stringent in their raw material selection, using only raw materials that meet environmental protection and high-performance standards, ensuring the quality of their WPC production lines from the source. During production, they follow standardized operating procedures, reducing quality fluctuations caused by human factors. Nanjing Saiwang Technology Development Co., Ltd. is one such company that has passed ISO 9001-2000 international quality system certification. Its products demonstrate excellent quality stability, providing reliable WPC production lines and reducing quality risks during the production process.

Authoritative Product Certifications: A Touchstone for Performance

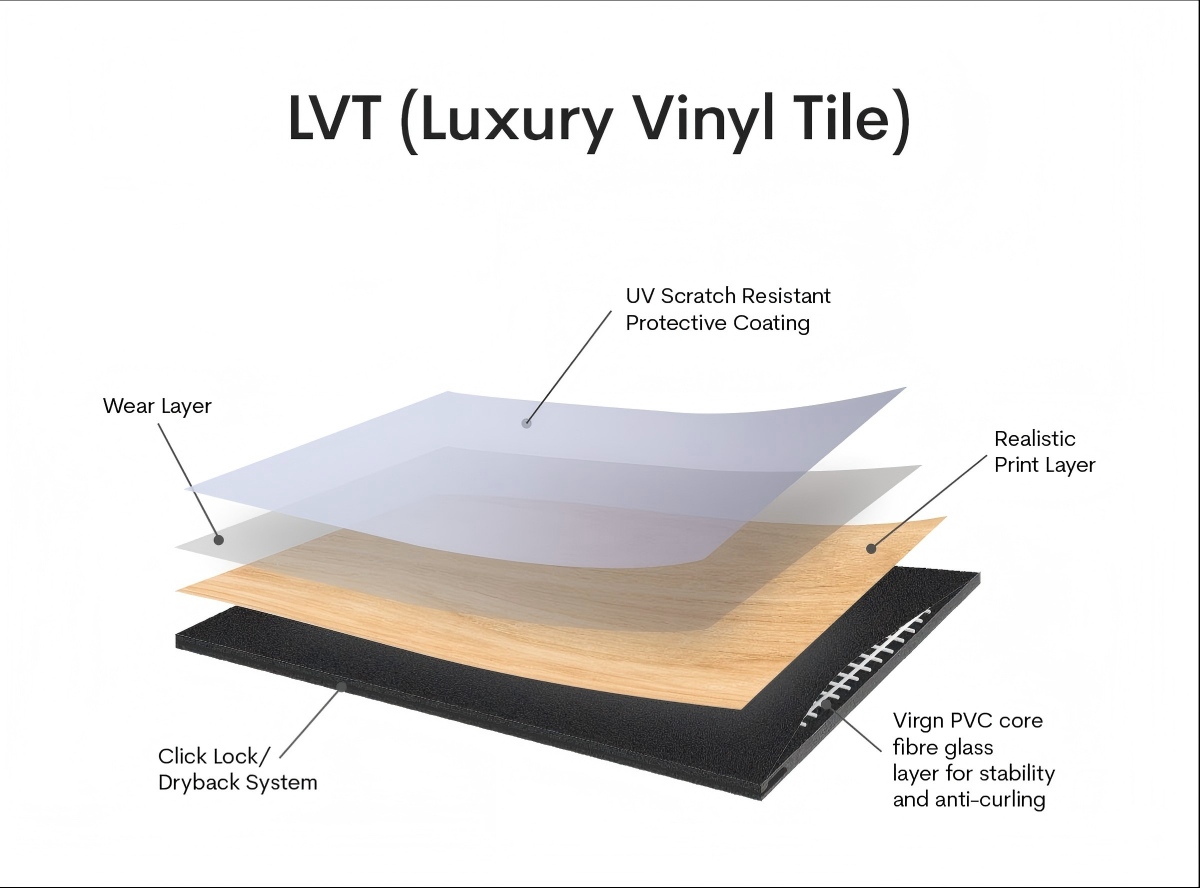

Besides quality system certifications, authoritative certifications of the product itself are also crucial. For example, the WPC production line being listed in the "National Catalogue of Environmental Protection Equipment and Products Encouraged for Development" by the National Development and Reform Commission indicates that the product meets national standards for environmental protection and technical indicators, and possesses high market recognition and application value.

Furthermore, EU CE certification serves as a "passport" for products entering the European market, imposing stringent requirements on product safety, health, and environmental protection. WPC production lines with CE certification meet European standards in electrical and mechanical safety, ensuring operator safety and facilitating international market expansion. SGS certification, from a globally renowned inspection, verification, testing, and certification body, ensures high credibility for WPC production lines, as they have undergone rigorous testing in product quality and performance. Nanjing Saiwang Technology's wood-plastic composite equipment has obtained both EU CE and SGS certifications, providing strong support for its international market entry and demonstrating the reliability of its product performance and quality.

When selecting a WPC production line, companies must pay close attention to these two certifications. They act like "double insurance," helping companies select reliable and high-performance production lines, avoiding common selection pitfalls, and safeguarding their WPC production journey.

Wide product range: Aluminum pickup truck camper, Fiberglass pickup truck camper, canopy, tent, roof car tent, RV accessories etc.

Wide product range: Aluminum pickup truck camper, Fiberglass pickup truck camper, canopy, tent, roof car tent, RV accessories etc.

Expandable Cabin Design: Innovative side-extension module increases interior space by up to 35%, offering more room for rest, storage, and family trips.

Expandable Cabin Design: Innovative side-extension module increases interior space by up to 35%, offering more room for rest, storage, and family trips. Wide product range:

Wide product range:  MOQ: just 1 set.

MOQ: just 1 set.