Choosing the right tunnel boring machine is very important. It helps your tunnel project succeed. If you pick a TBM that matches your project, you can control ground settlement. This also helps keep the work on schedule. The table below shows how picking a TBM changes settlement in tunneling jobs.

|

Project Count

|

Total Jacking Distance (km)

|

Maximum Recorded Settlement (mm)

|

Settlement Benchmark (mm)

|

|

22

|

4.518

|

13.1

|

10

|

You need a step-by-step plan to match the TBM to your project’s ground and goals. Careful checking makes the work safer and more efficient.

Key Takeaways

Key Factor in TBM Selection

Geology and Soil

You should first check the ground before picking a TBM. The type of soil and how hard the rock is will change how the TBM works. If the ground is hard rock, you need a hard rock TBM. These machines have broken world records in tunnel building. They often do better than old ways in soft ground. If the ground is mixed, it can slow down your work. It changes how fast the TBM can go and how long you work. You need to guess these ground types to keep the project safe and on time.

|

Evidence Description

|

Key Points

|

|

Hard rock TBMs have advanced tunnel construction significantly.

|

They set world records in tunneling, outperforming conventional methods in soft ground applications.

|

|

Encountering mixed strata affects TBM performance.

|

It impacts penetration rates and working hours, complicating advancement predictions.

|

You can use TBM data like cutterhead speed, torque, thrust, and advance rate to guess what is ahead. Good guesses help you stay away from dangers like rock bursts or tunnel convergence. These problems can slow down your project and cost money. Always pick a TBM that fits the ground for safety and good work.

Project Scope

You need to think about the size and goals of your tunnel job. A study of 112 top TBM projects showed geology is the main reason for picking the cutter type. After that, you look at the machine type and size. The project size tells you if you need a big or small TBM. You should also see if you need special features for your job.

Tip: Always check these things before you pick your TBM:

-

Machine type and what it does

-

How well it works

-

Technical details

-

How strong and tough it is

-

Safety rules and certificates

Safety and emergency plans are important for every TBM. You should also think about air flow, water, and noise. Special options help with tricky ground. If you use project software, make sure your TBM can work with it. This helps you watch your work and fix problems fast.

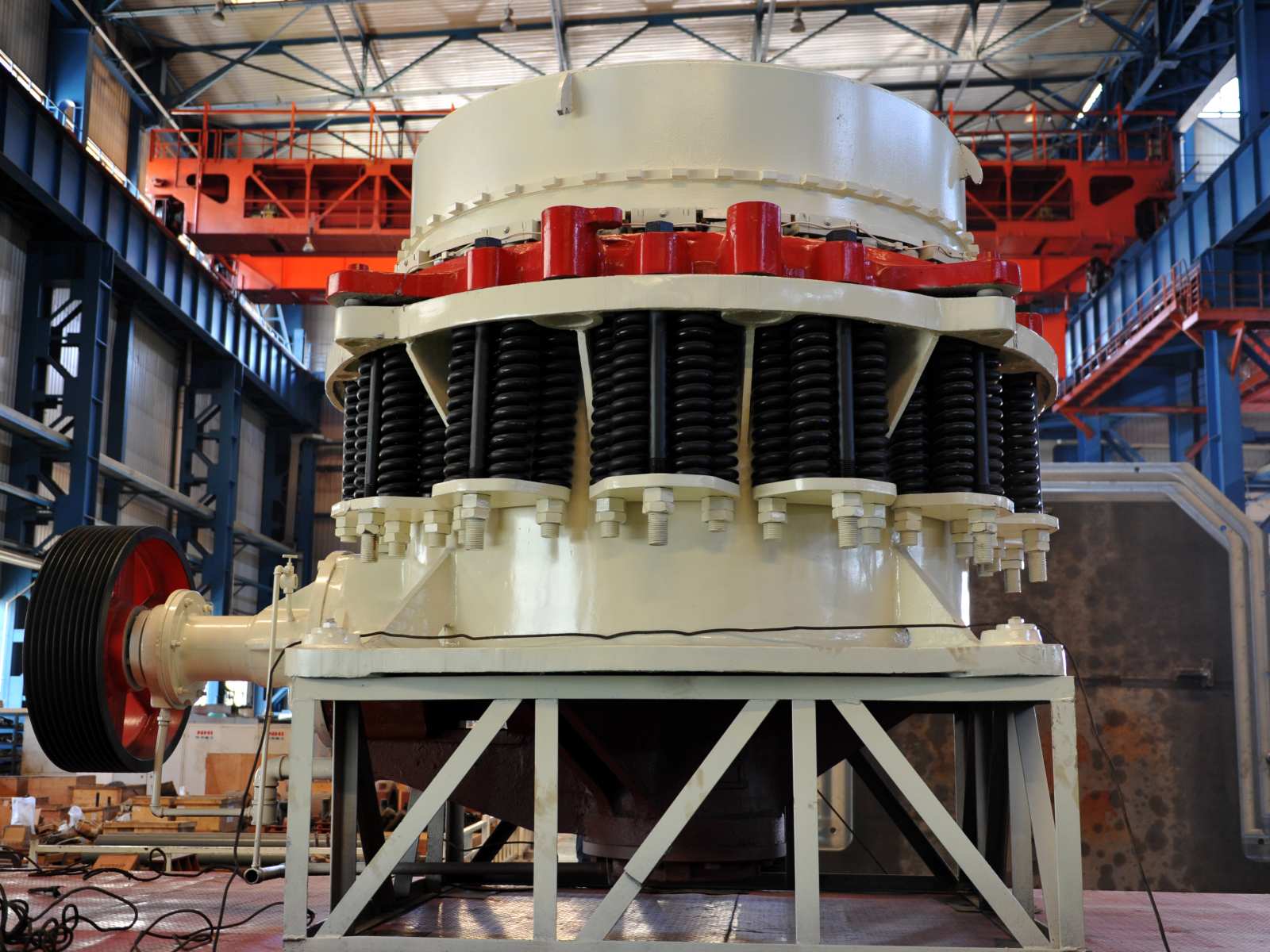

Types of Tunnel Boring Machines

When you begin a tunnel project, you should learn about the main types of tunnel boring machines. Each machine works best in certain ground and water situations. Picking the right machine helps you finish digging safely and fast.

Here is a table that shows how much each tunnel boring machine is used:

|

Type of TBM

|

Market Share Description

|

|

Slurry TBM

|

Shows clear dominance in the market

|

|

Earth Pressure Balance Shield TBM

|

Not listed in the evidence

|

|

Shielded TBM

|

Not listed in the evidence

|

|

Multi-Mode TBM

|

Not listed in the evidence

|

|

Others

|

Not listed in the evidence

|

|

Soft Ground TBM

|

Not listed in the evidence

|

|

Hard Ground TBM

|

Makes up most of the global market share

|

EPB Machines

Earth pressure balance tbms work best in soft ground. You can use them when there is water under pressure or in places with limestone or dolomite. These machines keep the ground steady while digging. You control the pressure inside the machine to match the ground outside. This stops the ground from moving and keeps your tunnel safe.

Tip: Use EPB machines for soft soils and places with lots of water. They help you handle tricky ground and keep your project moving.

Slurry Shield

Slurry tbms work well when there is a lot of groundwater. You use these machines when you want steady digging and fewer problems like clogging or cutter wear. In mixed ground, slurry shield machines keep working at the same speed. You do not see big changes in how fast they dig or how much energy they use. This makes them good for tunnels with lots of water or changing soil.

-

Slurry shield TBMs work well in wet places.

-

EPB machines can clog in high groundwater.

-

Slurry shield TBMs do not use more energy or dig slower.

Hard Rock TBM

Hard rock tunnel boring machines help you dig fast in tough rock. You get good quality, safety, and lower costs. These machines protect the environment and need less labor. You may have problems like cutter wear, jamming, steering trouble, water coming in, broken rock, or high stress in the rock. You should check the rock type before you pick this machine.

-

Good things: Fast digging, good quality, safety, saves money, protects the environment, less labor.

-

Problems: Cutter wear, jamming, steering trouble, water coming in, broken rock, high stress.

Open Face TBM

Open face tunnel boring machines work best in soft ground with little water. You can use them for rocks up to 10MPa strength. In cities, these machines make less noise and smoother tunnel walls. This helps you save money on lining.

-

Best for soft ground with little water.

-

Works for rocks up to 10MPa.

-

Good in cities to lower ground shaking and lining costs.

You should match your tunnel boring machines to the ground and water. This helps you avoid problems while digging and keeps your project safe and working well.

Tunnel Construction Requirements

Dimensions and Alignment

You need to plan the tunnel’s size and path before you start tunnel construction. The dimensions and alignment shape your entire project. First, you set the tunnel’s alignment. This means you decide where the tunnel will go underground. After that, you study the ground along this path. You look at the soil and rock to see what you will face during tunnel construction. The size of the tunnel tells you which tunnel boring machines you can use. Some machines work better for wide tunnels, while others fit narrow spaces. For example, earth pressure balance machines work well in soft ground. They help you control soil movement and keep the tunnel stable. If you match the machine to the tunnel’s size and path, you make tunnel construction safer and smoother.

Tip: Always check the tunnel’s alignment and size before you choose your machine. This step helps you avoid problems later in tunnel construction.

Groundwater and Environment

You must think about groundwater and the environment during tunnel construction. Water in the ground can cause big problems if you do not plan for it. You need to know how much water is in the soil and how much pressure it has. This helps you pick the right tunnel boring machines and plan for safe tunnel construction. The table below shows what you should check:

|

Consideration

|

Description

|

|

Geological Conditions

|

Check if the ground matches your machine and tunnel construction needs.

|

|

Soil and Rock Composition

|

Study the soil and rock to choose the best tunneling method.

|

|

Groundwater Presence and Pressure

|

Measure water levels and pressure to plan for pumping or sealing during tunnel construction.

|

In cities, you must follow strict rules to protect the environment during tunnel construction. Tunnel boring machines help you meet these rules. They make less noise and cause less shaking above ground. They also help you reuse machines for other projects, which cuts down on waste. When you work in soft, wet soils, earth pressure balance machines help you control ground movement. This keeps the tunnel safe and meets the rules for tunnel construction in busy areas.

Evaluating Tunnel Boring Machine Specifications

Performance Metrics

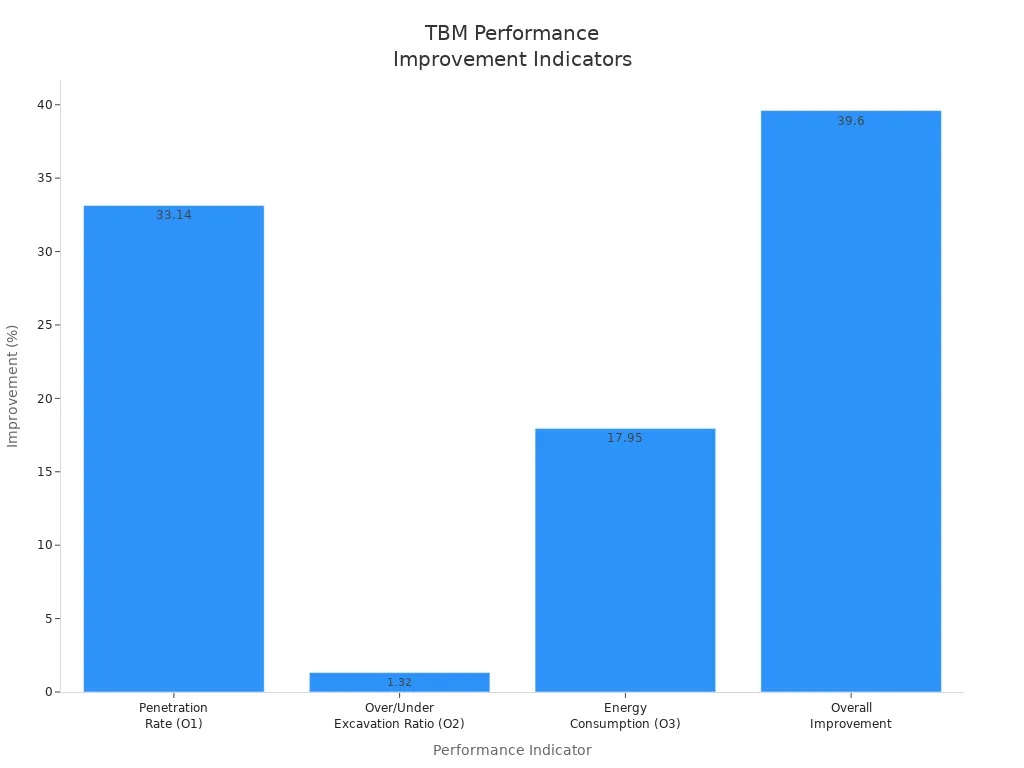

When you pick a tunnel boring machine, you should check how it works. You want a TBM that is safe and does a good job. The advance rate tells you how fast the TBM moves. If you know the advance rate, you can plan better and stop delays. A new deep learning method helps you guess the advance rate more exactly. This makes tunnel building safer and helps you work faster.

You also need to watch the torque of the cutting wheel. Torque shows if the TBM is working right. If the torque changes a lot, there could be a problem. It might be with the machine or the ground. By checking these numbers, you keep your TBM working well.

You can use special modeling software before you dig. This software uses machine learning to make your TBM safer. It looks at live data and changes how the TBM works. Robotic simulations let you test the TBM in different ground. You see how the machine will work before you use it.

|

Aspect

|

Description

|

|

Machine Learning Integration

|

Uses models to make TBM operations safer and more efficient in tunnel construction.

|

|

Real-time Data Analytics

|

Changes TBM settings based on live data, making material handling better during excavation.

|

|

Robotic Simulations

|

Tests TBM tasks before real excavation, helping you avoid problems and keep operations smooth.

|

You can use platforms like SMART to help you pick TBM settings. You choose things like face support pressure and advance speed. The software uses a special simulation to guess TBM performance in real time. This helps you make smart choices while building your tunnel.

|

Parameter Selection

|

Description

|

|

Operational Parameters

|

Lets you pick settings like face support pressure and advance speed for better soil-structure interaction.

|

|

Simulation Model

|

Uses advanced simulations to show how the TBM will perform during excavation.

|

|

User-friendly Application

|

Gives you easy tools to help you make good decisions while building your tunnel.

|

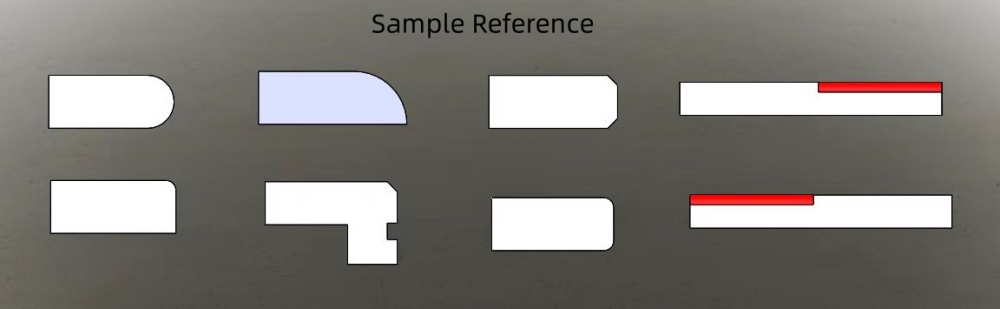

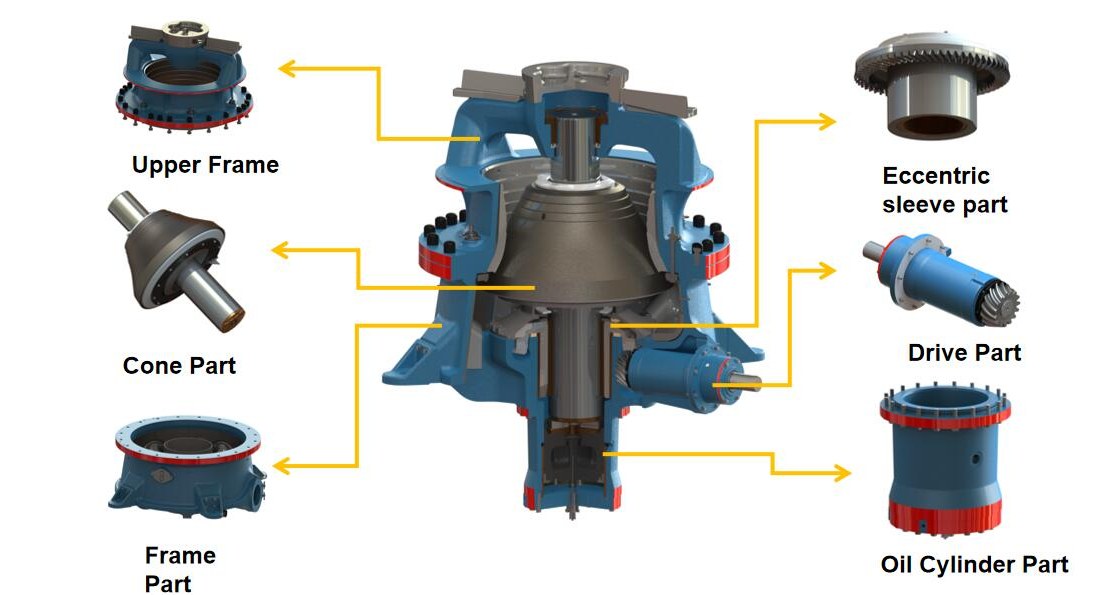

Cutterhead and Tooling

The cutterhead and tooling are important parts of your TBM. They help your machine work well in different ground. You need to match the cutterhead to the ground in your tunnel. If you dig in weak rocks, you want muck to travel a short distance. This makes digging faster and cleaner.

If you work in very hard or blocky rocks, use fewer openings. Arrange the disc cutters with more freedom. This setup lowers cutter wear and saves time. In mixed ground, you need a pressurized face TBM with enough openings. This design helps you avoid clogging and keeps digging smooth.

High abrasivity rocks need bigger cutters and a new cutterhead design. You want to arrange the cutters so they last longer. This means less daily maintenance. It helps your TBM work better and keeps your project on track.

|

Geological Condition

|

Cutterhead Design Considerations

|

Impact on Productivity

|

|

Weak Rocks

|

Reduce the distance of mucks running in the gap between tunnel face and cutterhead.

|

Enhances efficiency by minimizing muck interference.

|

|

Very Hard and Blocky Rocks

|

Prefer fewer openings and higher degrees of freedom in disc cutter arrangement.

|

Reduces excessive cutter wear and maintenance time, improving overall productivity.

|

|

Mixed Face Conditions

|

Use a pressurized face TBM with sufficient openings to minimize clogging risks.

|

Ensures smoother operation under adverse conditions, maintaining productivity levels.

|

|

High Abrasivity Rocks

|

Increased cutter diameter and re-evaluated cutterhead design to allow better arrangement.

|

Decreases daily maintenance time and enhances operational efficiency.

|

Tip: Always check the ground before you pick your cutterhead and tooling. The right choice helps your TBM work better and makes digging easier.

Safety Features

Safety features keep you and your team safe while building tunnels. Modern TBMs have many safety systems. Real-time monitoring gives you updates about the machine’s health. You see if there are strange vibrations or high heat. This helps you find problems early and keep your TBM safe.

Automated safety responses act fast if something goes wrong. The TBM can start emergency steps without waiting for you. Predictive maintenance uses data to find patterns. It tells you when a part might break before it happens. This saves time and money.

Emergency shutdown lets you stop the TBM right away in a crisis. This keeps everyone safe and stops more damage.

|

Safety Feature

|

Description

|

|

Real-Time Monitoring

|

Gives you live data on TBM health, showing issues like odd vibrations and temperature changes.

|

|

Automated Safety Responses

|

Starts emergency actions automatically to protect people and equipment.

|

|

Predictive Maintenance

|

Finds problems before they happen, cutting downtime and costs.

|

|

Emergency Shutdown Capability

|

Stops the TBM quickly in dangerous situations to keep everyone safe.

|

You should always look for these safety features when you pick a tunnel boring machine. They help you lower risks and keep your work safe.

Cost and Vendor Considerations

Purchase vs. Rental

When you plan your tunnel project, you must decide if you want to buy or rent a tbm. Buying a tbm costs a lot at first, but you own the machine. Renting or leasing gives you more flexibility, but it can cost more over time. You should look at your project’s length and budget before you choose.

Here is a table that shows the purchase cost range for different tbm brands:

|

TBM Brand

|

Purchase Cost Range

|

|

Herrenknecht AG

|

$5 million – $30 million

|

|

The Robbins Company

|

$10 million – $40 million

|

|

Wirth GmbH

|

$20 million – $100 million+

|

|

Qinhuangdao Tianye Tolian

|

$15 million – $20 million

|

|

Terratec

|

$10 million – $20 million

|

|

Hitachi

|

$5 million – $10 million

|

You can also look at other options:

-

Lease: Good for short-term needs, but may not have all the features you want.

-

Loan: Lets you own the tbm after the project and often has lower interest rates.

-

Rent: Works well for certain project phases, but can get expensive if you use it for a long time.

You should also think about where your project is. Moving a tbm takes careful planning. In cities, traffic and small spaces can make transport and setup hard. Sometimes, you need custom structures to help with installation. Fewer handovers and fewer people involved can help you save time and money.

Support and Service

Vendor support and service agreements play a big role in your tbm’s long-term costs. Good relationships with vendors can help you lower your operating costs. Many vendors offer maintenance and warranty packages. These packages help you manage expenses and avoid big repair bills.

You can save money by negotiating lease deals or buying more than one tbm at a time. Scheduled maintenance plans help you avoid surprise costs. When you work with a vendor who offers strong support, you keep your tbm running well and your project on track.

Tip: Always ask about service agreements and support before you choose your tbm. This step helps you avoid problems and keeps your project moving forward.

Future-Proofing Your TBM Choice

Modularity

When you pick a tbm, think about modularity. Modular designs let you change parts for new jobs. You can add features as your needs grow. This makes your tbm flexible and easy to fix. You get better access for repairs and upgrades. Here are some things to remember:

-

Modular equipment designs give you more choices for where you put parts and how you fix them.

-

You can change your tbm to fit different ground and project needs.

-

Good power and control systems help your tbm work well underground.

A modular tbm helps you solve new problems without buying a new machine. This saves you time and money on future jobs.

Software Upgrades

Software upgrades help keep your tbm working well. New software makes your machine smarter and faster. Upgrades can automate jobs, predict problems, and let you watch your tbm in real time. The table below shows how software upgrades help your tbm last longer and work better:

|

Feature

|

Benefit

|

|

Automation of Component Replacement

|

Cuts down on manual work and makes sure parts get changed on time, so your tbm works better.

|

|

Predictive Algorithms

|

Tells you when parts will wear out, so you can fix things early and stop delays.

|

|

Visualization of Components

|

Lets you see tbm parts in real time, so you can plan and manage better.

|

With good software, your tbm runs smoothly and you avoid big repair bills.

Technology Integration

Look for new technology when you pick a tbm. New tech helps you dig safer and faster. Automation finds problems before they get worse. Digitization makes it easier to run and fix your tbm. Real-time data analysis gives you quick updates on your tunnel.

-

Automation finds and predicts tunnel problems.

-

Digitization helps you run and fix your tbm better.

-

Real-time data analysis gives you important tunnel updates.

The table below shows some new trends in tbm design and use:

|

Technology Integration Trend

|

Description

|

|

Advanced Data Analytics

|

Makes work safer and better by watching things in real time and predicting when to fix them.

|

|

Machine Learning

|

Helps guess how your tbm will work, like torque and speed, so you can make better choices.

|

|

Automation

|

Makes tunnel work faster and easier, so tunnels last longer.

|

|

Eco-friendly Technologies

|

Helps build tunnels in ways that are better for the planet.

|

Using new technology gets your tbm ready for future jobs. It also helps your team work safer and smarter.

You can make tunnel construction go well by using a simple plan to pick your tunnel boring machine. Always choose a machine that fits the ground, your project’s needs, and what you might need later. Many problems in tunneling happen when people guess wrong about ground movement or forget about how joints work.

|

Common Mistakes

|

Description

|

|

Underestimating Ground Settlements

|

Not guessing ground movement right can hurt buildings above.

|

|

Overlooking Segment Cracking

|

Not checking forces during setup can crack concrete pieces or joints.

|

|

Ignoring Joint Behavior

|

Bad joint design or checking can cause leaks or parts not lining up later.

|

Check these things before you start building your tunnel:

-

Maintenance needs

-

How the machine will work

-

What makes the project a success

-

How much it will cost

-

What could stop work

-

Technical details

-

Effects on the environment

-

Safety parts

-

Help and service choices

Getting help from experts keeps your tunnel project safer and better planned. You get better results and your machine works well. Always talk to experts and vendors to get the best tunnel boring machine for your job.